|

|||||||||||||||

Used Machinery Used

Air Compressors Used

Sheet Metal Brakes Used

Duct Beading Machine Used

HVAC Duct Insulation Pin Spotters Used

Pipe Equipment Used

Sheet Metal Rolls

|

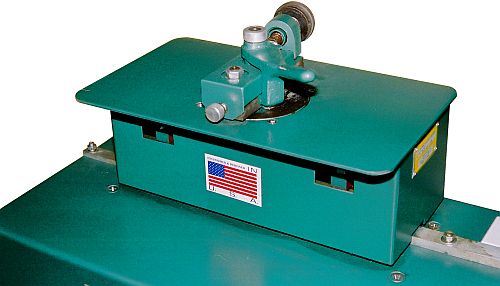

Tin Knocker Roll Formers | RollForming Machines

Tin Knocker TK T-D-P TDC Roll Former MachineTransverse Duct Connector Profile Roll Former Comes Standard

With: TDP Rolls, TDP Clip Rolls, TDP Clip Slitter & Feed

TK T-D-P Specifications:

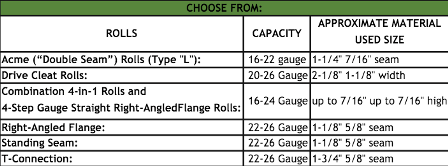

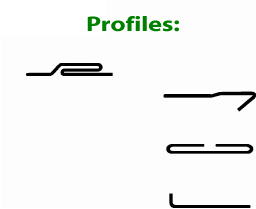

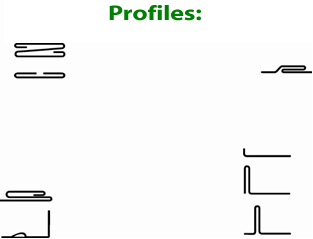

Tin Knocker TK 16 Ga Pitts Lock Roll Forming MachineThe 16 gauge Pittsburgh Lock machine has 7 forming stations with 2 forming positions. One position forms the Pittsburgh Lock, while the outboard position has the ability of forming a number of other profiles, to include: Acme, Drive Cleat or 4 in 1 rolls (3/16” Right Angle Flange, 7/16” Right Angle Flange, Standing Seam and T-Connection. You don’t pay extra for the choice of opposing rolls, either. You get your choice of rolls opposite the Pittsburgh rolls.

Tk 16 Ga Pittsburgh Specifications:

Tin Knocker TK 20 GA Pitts Roll Forming MachineThis 5 station 20 Gauge Pittsburgh lock rollformer is offered with choice of Drive Cleat or Acme rolls on the other outboard side. Powered by a 1 HP motor with V-belt drive.

**Optional Flanging Attachment TK 20 Ga Pittsburgh Specifications:

Tin Knocker TK 24 GA Pitts Roll Forming Machine With Stand & Optional FlangerPortable rollformer for 24 gauge and lighter material. It is available with power flanging attachment and is perfect for field use. Includes an all steel stand.

TK 24 Ga Pittsburgh Specifications:

Tin Knocker TK 20 Buttonlock Roll Forming MachineTin Knocker's 9 Station Button Lock Rollformer means no hammering over of edges. The Button Lock roll former comes with "male" tooling on one side and "female" on the opposing side. in Knocker’s 9 Station Button Lock Roll Former means no hammering over of edges and fast duct assembly. 220/3/60 Electrics, standard. A fast, effective way of marrying 20 to 26 gauge duct section.

TK 20 Buttonlock Specifications:

Tin Knocker TK Fourplex S & Drive Roll Forming Machine W/ Slitter AttachmentThe TK Fourplex machine comes standard with "S" Cleat & Drive Cleat rolls mounted inboard, and 2 sets of extended shafts for auxiliary tooling. A slitting attachment is also standard for slitting blanks for the "S" & Drive Cleats. This machine has two outboard Auxiliary Shafts which allow for your choice of Male & Female 20 Ga. Button Lock or 20 Ga. Pittsburgh, and 4-in-1 Rolls on the opposing side. NO OTHER STANDARD ROLL FORMER HAS A FASTER PAYBACK.

TK

Fourplex Specifications: Features:

Tin Knocker TK S & Drive Plus Cleat FormerThe TK S & Drive Plus roll former is a versatile machine of multi-functions. It slits the blanks to width and feeds either of the two roll roll sets. The machine comes standard with your choice of two sets of tooling. Most common examples: 20 Ga. Pittsburgh and 4-in-1 Rolls and Male & Female 20 Ga. Button Lock. It is fast, too. Many other roll sets to choose from… two sets included. The slitting feature allows you to quickly and easily turn scrap metal into usable product.

TK S & Drive Plus Specifications:

Tin Knocker No. 24 Collar Maker MachineNotch, bead, crimp and roll complete round starting collars, 3" to 14" in diameter out of 24 to 30 gauge galvanized - in only one pass. Just cut to width and length or use scrap. This machine uses either 3" or 6" width blanks with simple movement of the crimp roll.

TK No. 24 Collar Maker Specifications:

Return to the Tin Knocker Machinery Page Return to the New Machinery Page Return to the HOME PAGE |

||||||||||||||