|

|||||||||||||||

Used Machinery Used

Air Compressors Used

Sheet Metal Brakes Used

Duct Beading Machine Used

HVAC Duct Insulation Pin Spotters Used

Pipe Equipment Used

Sheet Metal Rolls

|

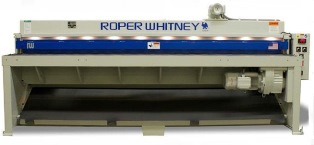

Roper Whitney sheet metal shears

Roper Whitney No.152 Shear

Roper Whintey Pexto Foot Squaring Shears are the industry’s most accurate. They are easy to operate and offer precise shearing, long life and dependability. All are provided with precise gauging and hold-downs for cutting accuracy. Maximum rated capacity is 16 gauge mild steel. No. 152 shears offer triple-action shearing which includes relief on both edges of both the fixed and moving blades. It eliminates blade-to-blade friction, provides “bite” to eliminate sheet movement under shearing stress and produces double penetration in the cutting action. This contributes to easier operation. The No. 152 will handle a 52″ sheet. *Lead times may be longer for this item.

Roper Whitney PH 52 and PH 452 Power Squaring Shears

Specifications Of The Roper Whitney Models PH452 And PH52 Power Shears:

Compact, fully-integrated, hydraulically powered shearing units. These shears are ideal for many light gauge shearing applications. Equipped with big shear operating controls. Fast, smooth, oil - cushioned action. Both moving and fixed blades are shearing blades of Hi-Speed steel. One piece cast shear bed is recessed for easy sheet handling. Standard equipment includes back, front, and side gauges, bevel gauges, front arms and transportation finger guard. Bed is machined for optional side extension squaring gauge. Other Features Of The Roper Whitney Power Squaring Shears Include:

Roper Whitney Pexto PX1214 Shears

Roper Whitney PX Series Mechanical Shears utilize a low maintenance design, coupled with an array of standard features for an attractive combination of high value and solid performance. The PX1214 incorporates a dual motor design. The dual motor design, of the PX Series, produces accurate distortion free shearing while minimizing machine twist. The system is capable of 45 strokes per minute. The PX1214 is ideal for high volume applications. The PX Series

also includes the unique 2R front operated

back gauge system. This allows the operator to move the

backstop from 0 to 30 inches in approximately 2 seconds with only

two rotations of the handle. A digital readout is standard for

this system. The PX1214 has an optional “Go-To”

30-inch powered back gauge system available. The ball screw-driven

back gauge provides quick, accurate cuts. The operator simply

inputs a dimension, and then presses enter, and the gauge automatically

positions to that setting. The Pro Package Includes:

Standard Features Of The Roper Whitney Pexto PX1214 Shear:

Specifications Of The Roper Whitney Pexto PX1214 Shear:

Optional Equipment Available:

Roper Whitney 10M14 Mechanical Shear

Roper Whitney's 10M14 Mechanical Shear utilizes a simple low-maintenance design, coupled with an array of standard features for an attractive combination of value and performance. The 10M14 capacity is 14-gauge mild steel, 18-gauge stainless up to 121.25 inches in cutting length. The electro-mechanical design of the 10M14 provides quiet operation with low power consumption. The shear is initiated by a moveable footswitch. An oversized shield and toe kick plate are incorporated into the footswitch for added operator safety. The 10M14 is capable of 35 cutting strokes per minute. For increased speeds please consult factory. The 10M14 Series shears are standard with an two edge interchangeable top and bottom, high carbon, high chrome top and bottom blades , independent, self-leveling hold down with neoprene insert, single, continuous and jog stroke cycles, motor reverse switch, precision-machined table, with dual inch/metric inlaid bed scales and non-metallic gibs. Non-metallic self-lubricating ram gibs ensure long life for the 10M14. Maintenance free self-lubricating bearings are standard.

Standard Features Of The Roper Whitney 10M14 Mechanical Shear:

Additional Options For The Roper 10M14 Mechanical Shear:

Rear Operated Manual with Precision Scale Front Operated Manual with Chain Drive and Position Counter DRO-Motor Driven with Digital Readout NC-Motor Driven with encoder Feedback, and Digital Readout with Five Preset Positions 10M14 Mechanical Sheet Metal Shear Specifications: |

||||||||||||||