|

|||||||||||||||

Used Machinery Used

Air Compressors Used

Sheet Metal Brakes Used

Duct Beading Machine Used

HVAC Duct Insulation Pin Spotters Used

Pipe Equipment Used

Sheet Metal Rolls

|

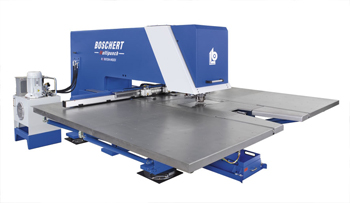

CNC Punching Machines

Boschert CNC Punching Machines EL SeriesPunching force to 60 Tons, Open C-frame construction, User-friendly graphic programming, Working ranges to 60" X 120", Full rotation to all tools available , revo tool multi tool solution available, Multiple configurations including 2 or 3 heads, Rotation and Revo Tool, Trumpf style or 28XX tooling, Automatic repositioning standard The EL Series of CNC Punching Machines from Boschert are workhorse machines for any fabricator. Some of the advantages are user friendly graphic programming, high quality with low cost, wide variety of configurations and options including: multiple heads, full rotation to the ram, RevoTool, engraving, forming and tapping. These Boschert Punching machines are extremely flexible including heavy duty c-frame construction allowing working of oversized sheets by turning and automatic repositioning function. The Boschert EL Series Punching Machines come in single, twin, or tri head configurations.

Boschert Punching Machine EL Series Specifications:

Boschert CNC Punching Machines CP SeriesA classic CNC punching machine, the Boschert CP Series puncher is composed of solid welded steel construction that can handle punching metal sheets up to 1/2” thick. Standard features include a TFT 10.5” color display, detached control panel, accuracy-focused construction, and industrial-grade CPU.

Boschert Punching Machines CP Series

Advantages: Specifications:

Mechanical Specifications: The Boschert Punching Machines are Extremely flexible: Heavy-Duty C-Frame construction allows working of oversized sheets by turning and automatic repositioning function.

Heavy duty clamps for work pieces up to 450 pounds. Boschert CNC Punching Machines Twin SeriesThe TWIN/TRI series machines are equipped, respectively with two or three independent punch heads. Either series can be equipped with Revotool, Boschert‘s multi-tool solution. Up to 16 tools in the TWIN series and up to 24 tools in the TRI series allow the working of complex parts without tool change. A distinct advantage of all Boschert CNC punching machines is the user-friendly software. The heavyduty, open C-frame design allows turning of oversized sheets. The powerful software suggests options for automatic repositioning and turning/flipping of large parts. Rotation Index

Boschert CNC Punching Machine Twin Series

Heavy-duty C-frame construction allows working of

oversized sheets by turning and automatic repositioning function Standard Features: Control Features: Other Features: Options:

Boschert CNC Punching Machines Tri SeriesThe TWIN/TRI series machines are equipped, respectively with two or three independent punch heads. Either series can be equipped with Revotool, Boschert‘s multi-tool solution. Up to 16 tools in the TWIN series and up to 24 tools in the TRI series allow the working of complex parts without tool change. A distinct advantage of all Boschert CNC punching machines is the user-friendly software. The heavyduty, open C-frame design allows turning of oversized sheets. The powerful software suggests options for automatic repositioning and turning/flipping of large parts. Rotation Index

Boschert CNC Punching Machines Tri Series Affordable, Versatile CNC Punching Standard Features for Boschert CNC Punching Machines

Tri Series: Control Features for Boschert CNC Punching Machines

Tri Series: Other Features on these Boschert Punches : Options for Boschert CNC Punching Machines Tri Series:

Repositioning of sheets up to 10 meters with no death zone

Boschert MP Series Multipunch For truly complex punching jobs, our Boschert MP Series Multipunch was designed to meet customer requests. Complete sheet processing is possible without operator intervention. Different die clearances can be used for various sheet thicknesses, allowing the MP Series machines to handle multiple repeating jobs in different materials.

Boschert MP Series Multipunch Machine Specifications: Boschert MP Series Multipunch Specifications Working Range: MP – 1250: 50″ x 100"; MP – 1500: 60″ x 120″

Boschert Ecco Line Series Manual Punching Machines For a punching machine with high performance, the Boschert Ecco Line Series Manual Punching Machines cannot be beat. This line is perfect for small and medium production runs, and single pieces and prototypes. All punching machines are equipped with at least 36 tons of punching force, and some with up to 60. A heavy-duty tool adapter with rigid ram guidance deliver precise punch and die alignment. You’ll also enjoy features like self-regulating overload protection, stripper holder and plate, Trumpf or 28XX Tooling System, maintenance-free hydraulic drive, constant punching pressure and a variety of available adapters.

Boschert Ecco Line Series Manual Punching Machines All EL Manual Punching Machines Equipped With: A digital readout can be mounted to all ECCO-LINE models to assure high accuracy when positioning the stops. Performance: Speeds: Tooling: Accuracy of Punching: Space requirement and weights:

Return to the Boschert Machinery Page Return to the New Sheet Metal Machinery Page Return to the Home Page

|

||||||||||||||