|

|||||||||||||||

Used Machinery Used

Air Compressors Used

Sheet Metal Brakes Used

Duct Beading Machine Used

HVAC Duct Insulation Pin Spotters Used

Pipe Equipment Used

Sheet Metal Rolls

|

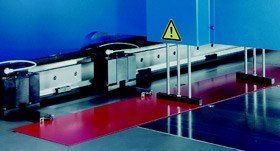

CNC Punching Machines

Boschert CNC Punching Machines EL Series

Boschert Punching Machine EL Series Specifications Punching force to 60 Tons, Open C-frame construction, User-friendly graphic programming, Working ranges to 60" X 120", Full rotation to all tools available , revo tool multi tool solution available, Multiple configurations including 2 or 3 heads, Rotation and Revo Tool, Trumpf style or 28XX tooling, Automatic repositioning standard The EL Series of CNC Punching Machines from Boschert are workhorse machines for any fabricator. Some of the advantages are user friendly graphic programming, high quality with low cost, wide variety of configurations and options including: multiple heads, full rotation to the ram, RevoTool, engraving, forming and tapping. These Boschert Punching machines are extremely flexible including heavy duty c-frame construction allowing working of oversized sheets by turning and automatic repositioning function. The Boschert EL Series Punching Machines come in single, twin, or tri head configurations. Specifications for the Boschert EL Series CNC Punching Machines:

Boschert CNC Punching Machines CP Series

Boschert Punching Machines CP Series More CNC Punching for Less Money....The CP Series

of CNC Punching Machines from Boschert Precision Machinery are

the perfect machines for production, short-run, one-off or prototype

work.

The Boschert Punching Machines are Extremely flexible:

Heavy duty clamps for work pieces up to 450 pounds. Boschert CNC Punching Machines Twin Series

Boschert CNC Punching Machine Twin Series Affordable, Versatile CNC Punching

Heavy-duty C-frame construction allows working of

oversized sheets by turning and automatic repositioning function Standard Features of the Boschert CNC Punching Machine Twin Series: - Automatic Pressurized Lubrication System Control Features of the Boschert CNC Punching Machine Twin Series: - Standard PC Controller Other Features for Boschert CNC Punching Machine Twin Series: - Pneumatic Material Clamps Options: - Rotation -- 360° Full Rotation Of

Punching Head

Boschert CNC Punching Machines Tri Series

Boschert CNC Punching Machines Tri Series Affordable, Versatile CNC Punching · Punching Force To 60 Tons Heavy-duty C-frame construction allows working of

oversized sheets by turning and automatic repositioning function Standard Features for Boschert CNC Punching Machines Tri Series: - Automatic Pressurized Lubrication System Control Features for Boschert CNC Punching Machines Tri Series: - Standard PC Controller Other Features on these Boschert Punches : - Pneumatic Material Clamps Options for Boschert CNC Punching Machines Tri Series: - Rotation -- 360° Full Rotation Of

Punching Head

Repositioning of sheets up to 10 meters with no death zone

Return to the Precision Machinery Page Return to the Home Page |

||||||||||||||